Our patented hydrophilic plugs & rings create a perfect, active seal around formwork spacers and tie rods. Discover now >

By adopting vertical integration principles, BeSealed® is able to respond rapidly to your company or industry's needs and requirements without having to rely on external partners. What does this achieve?

The highest possible quality under one roof, where it goes without saying that we provide innovation, flexibility and service. Your product or concept evolves from compounding through design to a finished product:

We develop a compound with adjusted expansion capacity and appropriate sealing characteristics. Our R&D department finds the right rubber compound for the job, taking into account your industry's specific needs and requirements.

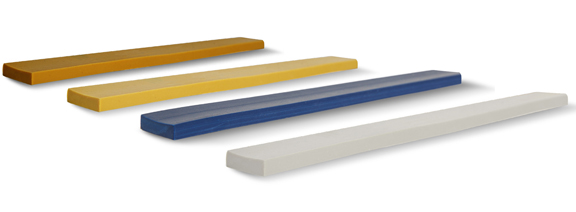

We design a suitable sealing solution with adjusted shape and colour. Based upon a 3D design, prototyping is being launched with a test mould.

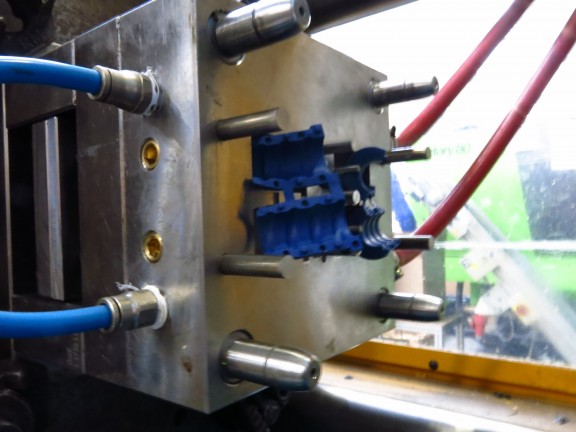

After final confirmation of the customer, the production mould is being installed on extrusion or moulding machines. The finished product is being produced. Virtually anything is possible, from products that expand in contact with salt water to electrically insulating compounds.

Our patented hydrophilic plugs & rings create a perfect, active seal around formwork spacers and tie rods. Discover now >

BeSealed® has a big range of hydrophilic profiles, perfect for sealing construction joints.

Discover now >>